Revolutionizing Warehouse Management with AI and RFID

In today’s fast-paced supply chain environment, warehouse operations are under increasing pressure to deliver faster, more accurately, and at lower costs. Traditional methods can no longer keep up with the scale and complexity of modern logistics. Enter two transformative technologies: Artificial Intelligence (AI) and Radio Frequency Identification (RFID).

Together, AI and RFID are reshaping how warehouses operate—bringing automation, real-time tracking, and predictive intelligence into the heart of logistics.

What is RFID?

RFID (Radio Frequency Identification) uses radio waves to identify and track tags attached to objects. Unlike barcodes, RFID tags don’t require a direct line of sight and can be read automatically and in bulk, making inventory management faster and more efficient.

How AI Enhances RFID in Warehousing

1. Real-Time Inventory Visibility

RFID tags automatically log the location and movement of items. AI systems analyze this data in real time to provide:

Accurate stock levels

Automated restocking alerts

Theft or loss detection

Optimized inventory placement

2. Smart Demand Forecasting

By analyzing historical data and RFID inputs, AI can forecast:

Product demand trends

Seasonal inventory needs

Optimal reorder times

This minimizes overstocking or stockouts and improves cash flow.

3. Optimized Warehouse Layouts

AI algorithms study item movements and frequency to recommend the best layout:

Fast-moving items placed closer to packing stations

Reduced walking time for pickers

Better use of space

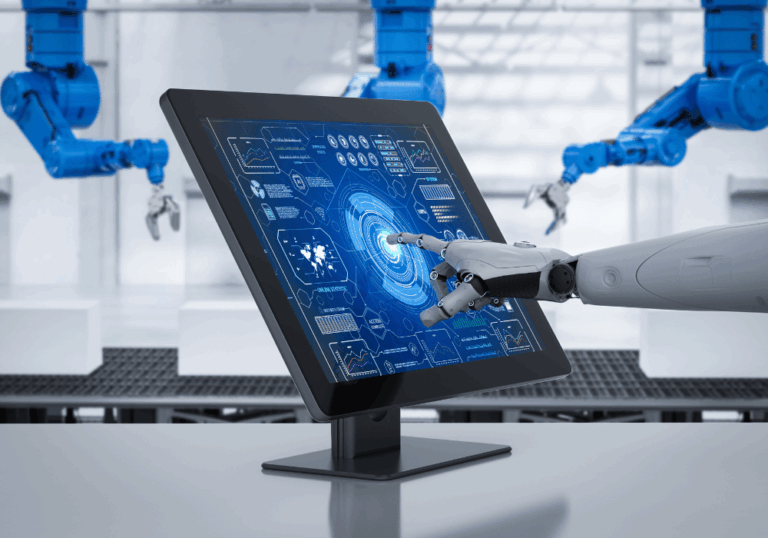

4. Automated Picking and Packing

When RFID tags identify item locations, AI-powered robots or human-assist systems can:

Map the shortest picking paths

Reduce picking errors

Streamline order fulfillment

5. Anomaly Detection and Maintenance

AI can detect unusual patterns in item movement (e.g., a missing pallet or repeated errors) and flag them instantly. This enables:

Preventive action before delays escalate

Equipment maintenance alerts

Improved quality control

Key Benefits of AI + RFID in Warehousing

✅ Increased visibility and control

✅ Reduced labor costs

✅ Fewer errors and losses

✅ Scalable and adaptive operations

✅ Competitive advantage in fast-moving markets

Final Thoughts

AI and RFID are no longer futuristic tools—they’re practical, proven technologies delivering real value to warehouses today. For businesses aiming to stay ahead in the logistics race, the question is no longer if they should adopt AI and RFID, but when.

Now is the time to invest in intelligent automation and transform your warehouse into a smart, efficient, and future-ready operation.